欢迎来到纽威包装技术(常州)有限公司!welcome to Neweigh Packaging Technology (ChangZhou) Ltd

欢迎来到纽威包装技术(常州)有限公司!welcome to Neweigh Packaging Technology (ChangZhou) Ltd

纽威-公司简介Company profile

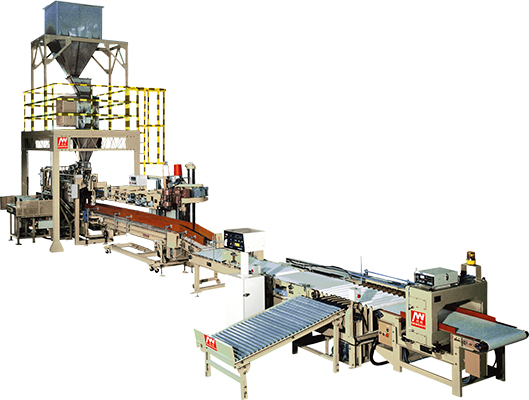

纽威成立初始,就非常重视技术研发队伍的建设、团队的培养,从最早期就一直完全地自主研发、制造各种物料的全自动计量、包装、码垛生产线、装车卸车系统和相关上、下游配套设备(比如:气力输送、称重配料等等),产品高速、安全、平稳地完成各种产成品物料(粉状、片状、粒状等)的全自动计量、自动灌装进包装袋/包装箱/包装桶,全自动地完成后续的封袋/封箱/封桶,全自动地完成后续的检测、码垛以及后续的堆垛进库房或全自动进运输车厢和从车厢卸车(适合各种规格的密闭的集装箱、运输车厢或敞开的车辆全自动装车、卸车);产品广泛运用于石油化工、化肥、粮食、饲料、冶金、建材、煤化工、精细化工等等行业及各种深加工产品行业。

中国的第一套TNT炸药全自动包装生产线(90年代末期),第一套铵油粉状炸药全自动包装生产线(2010年),第一套粉状乳化炸药全自动包装生产线(2014年,工信部目录…增26),第一套醇醚减水剂全自动包装生产线(2006年),第一套粉料聚丙烯全自动气力输送、包装生产线(2000年),第一套过磷酸钙、第一套甲酸钠、第一套碳铵、第一套氯化铵、第一套钾肥、第一套碳酸钙超细粉、第一套己二酸、第一套二元酸、第一套超细粉阻燃剂、第一套颜料、第一套氯化钠、第一套氢氧化钠、第一套氢氧化钾、第一套砒霜、第一套氢化钾、第一套氰化钠等等诸多料性较差、难以处理的物料的自动计量、包装、码垛生产线和后续的自动化物流装车卸车设备均由纽威自主研发、制造,设备长期稳定运行。

From the very beginning of the establishment, Neweigh has been always paying great attention to the technology research & development , and the professional team cultivating & construction. Totally depending on its own team , technology, and patents, Neweigh has been researching and developing the technology of fully automation for weighing, packaging, palletizing and loading & unloading systems/lines, and the according upstream & downstream equipment (e.g. pneumatic conveying, weight batching , etc.).The equipments of the system automatically finishes the high -speed operation of the final products (powder, pellet, flake ,etc.) to be fully automatically weighed in preset value, and then to be filled into bags/ barrels/boxes, and together with the other process of packaging, palletizing, loading /unloading the bags/boxes/barrels into or out of warehouse / vehicles (enclosed or opened carriages/containers) for transportation . It is widely used in various industries (e.g. petrochemical, fertilizer, grain, feed, construction material, metallurgy, coal chemical, etc. & the other various finished products of further processing and so on).

In China, the first line / system of the auto. weighing, packaging, palletizing, loading & unloading equipments for the flammable, explosive, hypertoxic, cohesive, dust fugitive finished products ,and so on, are designed, developed, manufactured by Neweigh, with long-term, stable , secure and reliable operation , such as the following:

TNT explosives (in 1999), ammonium nitrate fuel oil mixture(in 2010), emulsion explosive(in 2014,verified by Ministry of Industry and Information Technology of China in 2014),alcohol ether(in 2005), powdery PP (in 2000, patented technology) ,ammonium chloride, superphosphate, sodium formate, adipic acid powder, binary acid powder, calcium chloride , ammonium bicarbonate, sodium cyanide, editpotassium cyanide, arsenic powder ,etc.

Technical Specification for Fully Automatic Weighing, Packaging, Palletizing, and Loading/Unloading System of Various Models/Types

5.1.包装袋bag

5.1-1.包装袋材质bag materials:

①塑料编织袋(内表面涂膜或外表面涂膜)

PP woven bag with inner or out surface lamination

② 塑料编织袋内衬薄膜袋(外袋可不涂膜)

PP woven bag with inner PE bag

③其他材质的包装袋(如:PE袋,纸塑复合袋等)

Bags of the other materials(e.g. PE bag, craft paper bag,

paper bag with lamination, etc.)

5.1-2.包装袋的其他质量要求other requirements for bag:

①克重bag weight:110g/㎡,回生料包装袋亦可

recycled bags’material available ;

②表面尽可能平整,每只袋的尺寸一致(允许有少许不平整);

Surface is flat , & of same size for each bag

( tiny uneven surface is available);

5.2.包装桶、箱 box/barrel:

各种重量、材质均可全自动处理

various weight and textures are available;

1人不定期(每1小时左右)到现场巡视,添加包装袋的缝包线或封口带/

包装箱的封口带或扎带/包装桶的封盖或封条,添加包装袋/箱/桶,

处理一些正常设备维护等事宜(如有需要的话)。

1 operator ,at irregular intervals, inspecting the system at operation

site,adding new empty bags/boxes/barrels ,or new thread/ adhesive

tape /barrel bungs or covers to the according depots, along with doing

some maintenance (if needed).

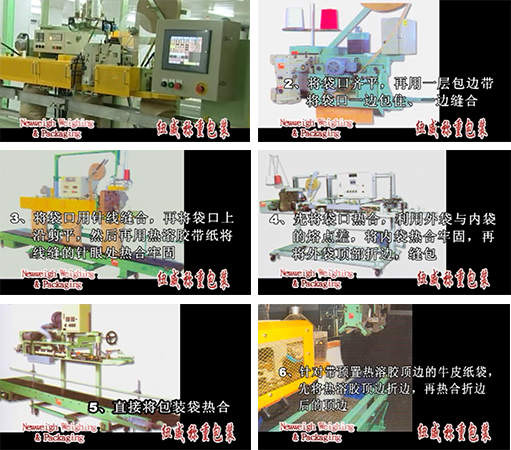

6.1、包装袋的封口bag sealing

1)将袋口折边,再用针线缝合;多用于一字边形的塑编袋、牛皮纸袋等袋的处理folding bag top(mouth), stitching the folded portion ;

2)自动齐边缝包(线缝)再用冷胶带包边(将针眼封牢,确保无粉 尘从针眼处漏出或外部杂质经针眼进入包装袋内);

Trimming the bag top(mouth),thread-stitching the bag top, covering & pressing mechanically the adhesive tape over the stitches ,preventing moisture/dust /powder from coming into or out of the bags through the stitch holes.

3)自动缝包(线缝)、用热熔胶带包边热合(将针眼封牢,确保无粉 尘从针眼处漏出或外部杂质经针眼进入包装袋内);

thread-stitching the bag top, covering the adhesive tape over the stitches , heat-sealing the adhesive tape, preventing moisture/dust /powder from coming into or out of the bags through the stitch holes.

4)自动袋口热合(针对PE袋)

auto. sealing the bag mouth by heat(only for PE bag);

5)根据用户现场的实际要求,满足各种其他的封口要求;

applying the other bag mouth sealing methods up to the actual requirements;

6.2、包装箱和包装桶的封口sealing for box/barrel:

根据箱盖、桶盖的密封要求,非标设计各种结构的全自动封口,高速、运行平稳可靠nonstandard designing of various sealing methods for various boxes ,and different barrels’ bung/cover for the according barrels, assuring the secure, reliable , stable & high-speed operation;

1人不定期(每1小时左右)到现场巡视,添加包装袋的缝包线或封口带/

包装箱的封口带或扎带/包装桶的封盖或封条,添加包装袋/箱/桶,

处理一些正常设备维护等事宜(如有需要的话)。

1 operator ,at irregular intervals, inspecting the system at operation

site,adding new empty bags/boxes/barrels ,or new thread/ adhesive

tape /barrel bungs or covers to the according depots, along with doing

some maintenance (if needed).

ABOUT US

扫一扫,关注我们

扫一扫,关注我们

CONTACT

备案号: